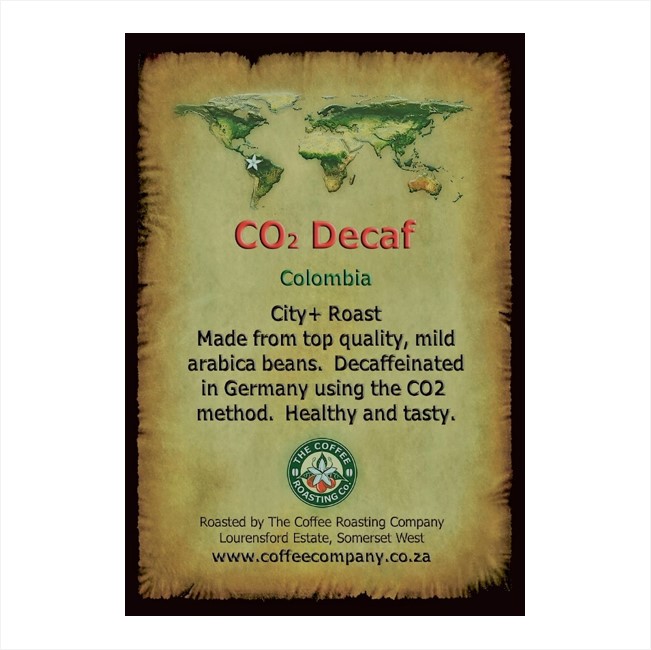

Colombia – CO2 Decaf – Single Origin Green Beans – 1kg

R350,00

Unroasted Green Bean

Made from naturally low caffeine top quality Arabica beans. Decaffeinated in Germany using the CO2 method.

Description

The CO2 decaffeination process, also known as the supercritical carbon dioxide method, is one of the most popular techniques for decaffeinating coffee. This method uses carbon dioxide (CO2) in its supercritical state to extract caffeine from the beans while preserving the flavour compounds.

Steps in the CO2 Decaffeination Process:

- Steaming:

- The coffee beans are first moistened with water and then steamed to make them swell. This prepares them for caffeine extraction by opening up their pores.

- Pressurizing with CO2:

- The beans are placed in an extraction vessel.

- CO2 is applied at high pressure (typically between 73 to 300 times atmospheric pressure) and moderate temperature (around 31°C or 88°F). Under these conditions, CO2 becomes a supercritical fluid, which has properties of both a gas and a liquid. This supercritical CO2 can penetrate deep into the beans or leaves.

- Extraction:

- The supercritical CO2 acts as a solvent to selectively extract caffeine molecules from the beans.

- The CO2, now laden with caffeine, is moved to a separate chamber called the absorption chamber.

- Caffeine Removal:

- In the absorption chamber, the CO2 is depressurized, which causes it to return to its gaseous state. During this process, the caffeine separates from the CO2 and can be collected.

- The now caffeine-free CO2 can be reused in the extraction process, making it an environmentally friendly method.

- Drying:

- The beans are dried to remove any remaining moisture. This step restores them to their original state, minus the caffeine.

Advantages of the CO2 Decaffeination Process:

- Preservation of Flavor: The process is selective for caffeine, leaving most of the flavour compounds intact, resulting in a decaffeinated product that retains much of its original taste and aroma.

- Environmentally Friendly: CO2 is a naturally occurring compound, and the process allows for its recycling and reuse, reducing environmental impact.

- No Harmful Solvents: Unlike some other decaffeination methods that use chemical solvents like methylene chloride or ethyl acetate, the CO2 process avoids potentially harmful chemicals.

Applications:

- Coffee: This method is widely used in the coffee industry to produce decaffeinated coffee that maintains a flavor profile similar to regular coffee.

- Tea: It is also used for decaffeinating tea, ensuring that the tea retains its original flavor and health benefits.

The CO2 decaffeination process is favored for its ability to produce high-quality decaffeinated products while being environmentally responsible.

Additional information

| Weight | 1 kg |

|---|